While it may seem a waste of time for us today, living – as we do – in the era of inexpensive, stainless razor blades, less than a century ago people actually stropped their razor blades in order to keep them sharper for longer. A number or razors even came with blade holders in order to make this process easier, but what if your razor didn’t come with one, or you had several different razors you wanted to strop the blades for?

Fear not, because in 1930 Mr David J Prince patented an improvement to the safety-razor-blade holder that would accept any major blade on the marked!

…a convenient, inexpensive holder for razor blades when it is desired to sharpen the same by stropping and it particularly seeks to provide a holder which will take either Valet, Christy, Gillette or Durham type blades, or those having backs such as the Gem, EverReady, Star and other well known kinds.

David J Price

For those who are not familiar with the different blades, that don’t sound too difficult.. but one have to keep in mind that this would include single and double edged blades, with and without holes and slits, with and without ears, and with and without a thick spine along the back. All told an impressive range of shapes and thicknesses that the design have to account for.

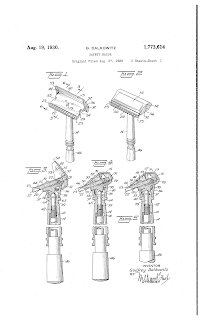

As can be seen from the patent drawing, the blade holder consisted of two hinged plates that clamped the blade between them. Since each plate had ‘half’ a screw on the end, tightening the handle on the blade holder locked the two plates together and clamped the blade securely. Or as the patent describes it, each plate:

…has a threaded shank 2 at one end and a hinge ear 4 at the other end, the threaded shank having a portion cut away.

David J Price

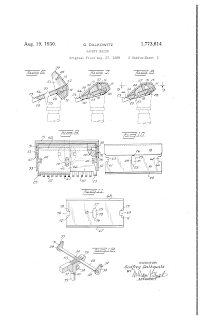

The plates had groves or cutout int he middle of them as well as a couple of holes drilled through, and for different blade styles there would be different ways for securing the blade;

- for Durham, Gillette and Varlet blades, there was a pair of loose studs (called lugs in the patent text) that lined up with the holes cut in the blade

- for Christy style blades, the studs were removed

- and a GEM style blade would rest in the groves themselves

All told a simple and ingenious solution to the problem of providing clamping pressure on a variety of blades -as long as you didn’t loose the two studs that is. One improvement I can see immediately would be to give the studs threads on the part that fitted into the holes in the holder – said holes would have to be threaded too – and when stropping a blade without holes simply fasten them on the outside of the plate.

I can also see this being useful as a simple, cheerful and somewhat scary kamisori-style shavette – one that allowed a shaver to experiment with several different styles of blades, although the selection in this day and age is smaller than it was in the late 20’s and early 30’s.1

As far as I can tell, this is the only razor or shaving related patent Mr Price filed for, which is a shame, cause I would have loved to see if he could come up with a razor that fitted multiple styles of blades as well.

- For starters, there is to the best of my knowledge no one that manufactures

Valet, Durham orChristy style blades any longer. Update: I’m informed that Feather still makes blades that fit Valet and Durham razors.