The old vintage Ever-Ready and GEM razors from American Safety Razor Corp used a single edged blade different from the GEM blade we can buy today, as can be seen in the photos of one of my old unused – practically NOS – Ever-Ready blades and a fresh GEM blade from my stockpile.

As can clearly be seen the original Ever-Ready/GEM blade was thicker, with a much thicker spine, and had no cutouts. While you can use a modern blade in the original Ever-Ready and GEM razors – such as the 1912 and 19141 – you can’t use the original blade in a slightly more modern GEM, such as the various Micromatics. This is because the more modern razors uses the cutout to align the blade, and a blade without a cutout would stop the razor from closing properly.2

So logic dictates that the change in blade came about the same time as the GEM Micromatic was designed… Say hello to Marcus B Behrman’s patent filed and granted in 1929, describing not only what is in effect the modern GEM blade, but also the double edged single edged GEM blade I wrote about last week and a razor designed to utilise the new blade.

The invention aims primarily to provide a razor blade having special features of construction by the use of which the above mentioned adjustment of the blade with reference to the stops may be carried out with greater effectiveness and certainty, certain additional features of construction being preferably employed in the blade to insure that during assembly it will be preliminarily positioned within the proper range of action of the mechanism employed to press it against the stops.

The invention also includes a novel blade holder adapted to cooperate with a blade of the nature above referred to, to press the blade against the stops as aforesaid.

The function of, and the rationale behind, the cutouts in the blade – which was a radical departure from the original GEM blade – was quite well described in the patent:

To enable the blade to be effectively pressed against stops of the nature above referred to, I will provide it with cut-away portions and 26, located adjacent its opposite side or end edges and rearwardly of its shaving edge, these cut-away portions thereby presenting abutment shoulders 23 and 24 between t e cutaway portions and the shaving edge 20, which may be engaged by properly cooperating movable parts on a blade holder, to press the blade cutting edge against the stops on the holder as aforesaid.

The specific claims for the single and double edged variations of the blades were summarised as:

A safety razor blade having a shaving edge provided with stop engageable corner portions and cutaway portions in the central zone of the blade and in the opposite sides thereof, said cutaway portions presenting abutment shoulders therebetween and said shaving edge, said blade also having an opening between said cut-away portions with elongated linear side walls running transverse to said shaving edge to guide said stop engageable corner portions to their final predetermined stopping position.

A double edged safety razor blade having substantially parallel front and rear shaving edges provided with stop engageable corner portion, and cut-away portions adjacent opposite side edges which present abutment shoulders respectively spaced substantially equally from said front and rear edges, said blade also having an opening disposed substantially centrally between said cut-away portions, said opening being elongated in a direction transverse to said first mentioned edges and having end walls spaced substantially equally from the respective adjacent front and rear edges.

The form and function of the razor is also discussed at great length in the patent, but it’s mostly a variation on the previous GEM razors… the twist to open Micromatics must have been developed somewhat later.

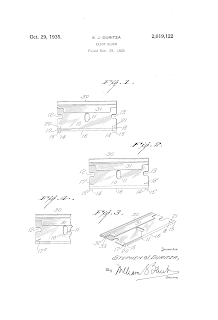

As an interesting aside, a US patent filed for in 19303 also came to the surface as I was searching.

Filed by Stephen J Duritza, the preamble makes no secrets of which razor the new blade was meant for:

My present invention relates generally to razor blades and more particularly to the type of razor in which the shaving edge of the blade is to be received against front aligning stops to give such edge its predetermined position or relationship. Example of such type of razors are those known today as the “Gem” and the “Ever- Ready”.

Interestingly, the reason given for coming up with the new blade design wasn’t to simplify production, improve alignment, or give better shaves.. but to stop the corners from bending:

Where razors of this character are dropped on the floor or brought suddenly against a hard surface, it is generally the corners either of the blade seat or of the clamping cover where such clamping cover is employed, which receives the force of the impact, and may result in the bending of such corners. Where such bent corners engage the blade either at or adjacent to the shaving edge there may be the tendency in such a case for the shaving edge to be distorted from its true straight alignment for its most efficient shaving.

It is one of the objects of my invention to so arrange, treat or construct sections of the blade that this tendency to distortion under these conditions will be minimized or wholly eliminated.

Off course, not dropping your razor in the first place would been preferable – but if you do, it’s nice if you don’t have to replace the blade. What Mr Duritza did to avoid transmitting the shock of impact from the blade stops was to mechanically decouple the edge from the corners with a couple of slits. In the words of the patent:

If this fall results in a deformation of one of the aforementioned parts, this deformation would tend ordinarily to distort the non-functioning section of the shaving edge opposite thereto and this distortion would be transmitted to the active shaving edge. By providing the cuts 17 and 18 as hereinabove explained, the distortion will be taken up by the blade sections 20 or 21 as the case may be and will not be transmitted to the active shaving edge 16.

While the patent that gave rise to the modern GEM blade resulted in production that goes on to this day, Mr Duritza’s patent seems to have gone no where… perhaps the bending of the blade edge from dropping the razor was less of an issue than the inventor believed it to be? The Double Edged GEM blades also seems to have gone the way of the dinosaurs, sadly, but in the days before stainless blades I’m not too surprised about that – by the time you got to flip the blade over, the humidity and soap residue might have done a number on the second edge.

1) It will rattle a little until you close the razor, and a bit of care has to be taken – at least with my 1914 – to make sure it’s aligned properly.

2) This backward compatibility is similar to how you can use a modern slotted double edge blade in an original Gillette Old, but you can’t use a three holed blade in a Gillette Super Speed.

3) not granted until almost five years later though; the wheels of bureaucracy turns slowly at times.

Pingback: GEM’s Micromatic – can’t nip, won’t skip | Wegian Wetshaving

Pingback: John Monks' shaving apparatus - Wegian WetshavingWegian Wetshaving

Pingback: Jeremiah Reichard's 1906 Lather Catcher - Wegian WetshavingWegian Wetshaving

Pingback: 1936 Micromatic advertisement - effortless shaving - Wegian WetshavingWegian Wetshaving

Pingback: Guy Osborn's Shrp-Shavr patent - Wegian WetshavingWegian Wetshaving

Pingback: Louis Heckel's safety-razor-blade holder - Wegian WetshavingWegian Wetshaving

Pingback: Fingerspitzengefühl razor - Wegian WetshavingWegian Wetshaving