Category Archives: VintageRazor

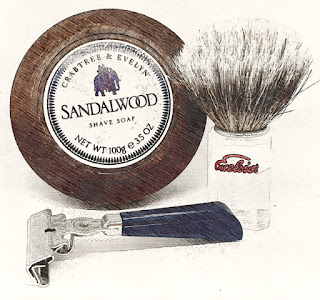

Shave of the day 14th February

Razor: GEM Micromatic Clug Pruf

Blade: GEM Single Edge Stainless

Pre-Shave: The Lavish Gentleman Charcoal Mask

Lather: Prep “The Original Formula”

Aftershave: Barber No3 Marmara

Additional Care: Alum Block, Gentlemen of Sweden Original Beard Oil, & Pereira Shavery Boomerang Beard Comb

The double edged single edged blade

Sounds like a contradiction in terms, but today I learned that GEM introduced a single edged blade in 1948 – although some sources states that it was sold during WW2 – that had two edges. Be basic idea was that you could flip it over once one edge was dull, in effect giving you two blades in one.

A little bit of searching on line has so far not revealed how they shaved, but the fact that they would only fit the Micromatics and we can’t get them no more seems to indicate that they wasn’t a run away success.

Shave of the day 12th February

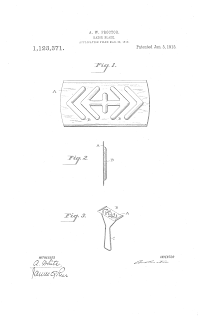

Gillette’s thin, rigid razor blade

Razor blades – by which I mean the traditional double edged blade – is flexible. This is because it’s made out of thin steel, even thinner now than when King Gillette first though them up.1 But flexible blades needs a rigid holder – better known as a safety razor – and as we all know a razor costs money up front. Imagine how many more blades you could sell if the holder – the razor – was significantly cheaper?

This seems to have been the logic behind the patent that Alfred W Proctor filed on behalf of the Gillette Safety Razor Company in 1912. In the words of the patent text:

This invention relates to razor blades of a type now widely used and made of thin sheet steel, as distinguished from forged blades. The facility with which such blades can be manufactured because they do not require forging in order to bring them to shape and because many of the grinding processes incident to the production of a forged razor are unnecessary, has brought them into wide use. Blades made from such thin sheet steel, however, have an inherent flexibility which requires, or at least, makes it desirable to employ With them a holder which embodies a backing, this holder operating to support the blade and impart a certain degree of rigidity to the cutting edge. Such holders are however expensive to make and are undesirable for various reasons.

The holder that supports the blade and imparts a certain degree of rigidity to the blade that Mr Proctor refers to is – as all of you probably realises – the actual razor itself. Personally I cannot see the razor being undesirable for any reason, but it’s certainly true that the double edged blade requires both a bottom plate and a top cap to hold the blade securely and to prevent the blade from vibrating and chatter.

So how did Mr Proctor plan to make the Gillette safety razor – which had been on the market for less than a decade when this patent was filed – obsolete? By making the blade stiff enough to do without the rigidity of the holder – ie.: the razor – much like a straight edge razor. Not by making the blade out of thicker materials, but making it thicker by putting ribs or ridges in it.

In order to impart the necessary or desirable rigidity referred to the blades will be given a configuration which affords such rigidity so that the blades because of their configuration are stiffened.

For the exact same reason that an I-beam is stiffer than a plate, a blade with ridges is stiffer than a blade without.2 And if the blade is stiff and rigid, you can do without the complex holder – that is; the razor. And thus we end up with the invention shown in the patent drawing: A blade with ribs arranged to make it stiff both along it’s length and breath, and a razor that was little more than some bent wire.

The blade may be used in a wire frame such as C which operates merely as a holder and does not impart any appreciable degree of support to the blade.

I think that when all is said and done we ought to be happy Gillette didn’t go down this road, since we would have missed out on so many fun and wonderful razors in the last century.

1) For more details, see my previous blog post on how old razors shaved back when new. The quick summary is that modern blades are half as stiff – or twice as flexible – as the original blades.

2) For the technical details, read up on Euler–Bernoulli beam theory, also known as engineer’s beam theory or classical beam theory. The quick, oversimplified summary is that the taller the web (or the ridges, in the case of this patent) the stiffer the beam (in this case; blade).

A Double Edged Schick razor

An advertisement in The Jackson Tennessee Sun newspaper from 11th February 1968. Before I found this I wasn’t even aware that Schick had manufactured double edged razors.

I mean, I shouldn’t be too surprised – after all it’s all about market shares, and no sane company would give up the opportunity to compete head to head once patent rights on the double edge blade and razors had expired. And Schick do own – as far as I know – Wilkinson Sword, which do manufacture both blades and double edged safety razors still.

Combined comb and hair cutter

Long time readers of my blog will – perhaps – recall I posted a quick little post about a home made hair trimmer made with a comb, a razor blade and some painters tape a few years ago. To no one’s surprise this wasn’t a new idea – you can buy a dozen variations in all sort of shapes from Chine – but I found an early patent that seems to be inspired by the top cap of a Gillette razor.

Applied for by Mr Domenico Marrazzo in the fall of 1935, the device was claimed to be for the head as well as other parts of the body.

… a combined comb and hair cutter, wherein the blade is so guarded as to prevent accidental i6 cutting of the fingers and to permit the hair cutting portion to be used as a handle when the comb portion is used as a comb.

So hold one end of the device, and it’s a comb. Hold the other end, and it’s a hair cutter. Hope that you remember which end is which when you brush your hair before going on your big date.

It’s a simple enough idea in hindsight – like most good inventions are – and Mr Marrazzo took care to point out that you could make it from almost anything, ad that it would be usefull for anyone regardless of hair length:

The comb may be made of any suitable material such as hard rubber, bakelite or metal such as aluminum or the like.

Said arcuate portion is somewhat greater in length than the length of the blade 14 and has a convex outer surface 11 and a concave inner surface 13 as shown in Figs. 2 and 3. In order that the device may be operative in cutting long hair as well as short hair, the row of teeth 20 on one side of the comb are preferably longer and if desired, coarser than the opposed row 21 on the other side.

All told it sounds like a useful combination tool for those who like to trim their own hair – as highlighted by the fact that variations on this theme is still for sale.

So safe you can shave in the shower

Are Schicks better than good old double edged razors, or is it mostly marketing spin? They do point out one of the things I like about injectors though; the ease of getting the correct angle. Simply place flat against the cheek and shave.

If I were to recommend a classic safety razor for a new wetshaver today, and s/he didn’t mind buying a vintage razor second hand, I would put a Schick injector near the top of the list simply due to the ease of learning it.

Single edge razor of of simple and economical construction

From time to time I come across patents that I’m sad didn’t make it into manufacture… and the single edge razor Mr Frank Pelosi was granted a patent for in May 1931 is one of them. It just looks, well, nice.

Mr Pelosi didn’t claim that his razor would be the best thing since sliced bread, nor that it would be a quantum leap over other razors… just that it would be, well, simpler and better. In his own words:

…an improved razor of this type which comprises a relatively few parts of simple and economical construction, which permits easy and speedy insertion or removal of a separable blade, and which may be small in size and light in weight without sacrifice of operative efficiency.

It’s was a simple twist-to-open open comb razor, which indexed the blade on a rivet mounted on the bottom plate, while the top cap was made from sheet metal and tightened by a knurled knob on the end of the handle.

…the razor comprises a handle 10 having an axial opening 11 therethrough, a guard member 12 mounted in one end of the handle, a rotatable knob or lock nut 13 at the opposite end of the handle, a lock plate 14 arranged to cooperate with the guard to hold a blade 15 therebetween, and an adjusting. stem 16 extending through the hollow handle and having one end engaging a threaded opening 17 in the nut 13 and its opposite end passing through an aperture 18 in the guard 12 and secured to the lock plate. as by a rivet or pin 19 which projects through an opening 20 in plate 14 and is headed over on the top surface of the plate. The stem and lock plate may thus be moved longitudinally of the handle by rotating the lock nut to secure the blade in working position (Fig. 3) or to separate the plate from the guard member and permit insertion or removal of the blade (Fig. 4).

Overall Mr Pelosi’s razor gives the impression of a well though out, workmanlike razor with no frills and only a little thrills. What killed it in the marked was probably the fact that it required it’s own special blades, requiring setting up manufacture of not just the razors, but also the blades.