There is – as the saying goes – nothing new under the sun… Apparently Feather have come up with a new innovation to reduce the friction when shaving; namely a roller:

Except… it’s not all that innovative. At all.

How about a 1903 Mandarin SE (manufactured until 1914 in Germany)?

Or a Roller Guard after-market baseplate for your Gillette, patented May 7 1929? Also, you could apperantly get after-market parts for your razors back in the day, dispelling the idea that razors were cheap.

You could also get the Roller Razor as a full up three piece razor.

Or how about a variant of the J. A. Henckels Rapide, circa 1920’s?

Or perhaps a lovely Wilkinson 7 day set from the 1940’s?

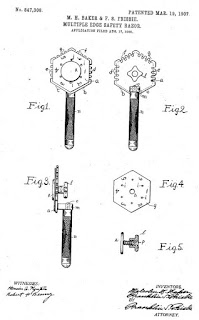

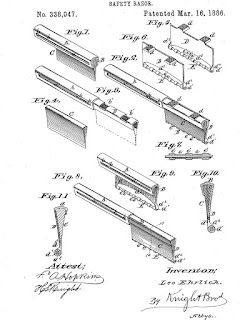

In fact the oldest patent I could find for rollers on a razor dates back to 16th March 1886! To quote:

My invention consists partly in application to a razor of a roller acting as a guard to prevent the wounding of the skin in the use of the razor, and partly in certain details of construction pointed out in the claims.

Unsurprisingly the razor isn’t a safety razor as we know it:

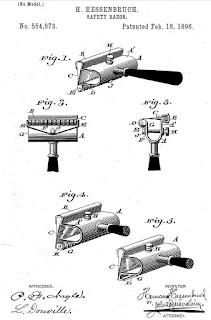

The oldest patent I found for a hoe-style – the blade 90º on the handle – safety razor with rollers I could find with a quick search is ten years younger, from 18th February 1896. Still fairly respectable, and it was even adjustable with a screw so the user could dial in how aggressive it should shave.

So while I can respect Feather for doing something unusual it is not innovative.

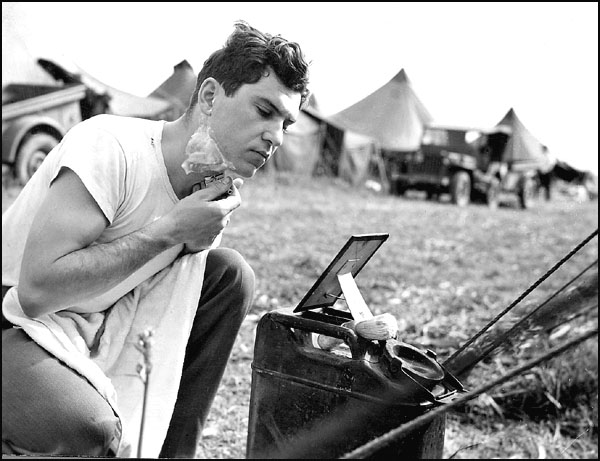

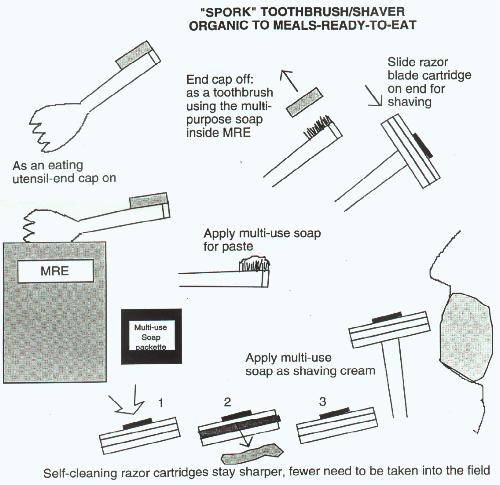

Like this:

Like Loading...