Monthly Archives: January 2020

So safe you can shave in the shower

Are Schicks better than good old double edged razors, or is it mostly marketing spin? They do point out one of the things I like about injectors though; the ease of getting the correct angle. Simply place flat against the cheek and shave.

If I were to recommend a classic safety razor for a new wetshaver today, and s/he didn’t mind buying a vintage razor second hand, I would put a Schick injector near the top of the list simply due to the ease of learning it.

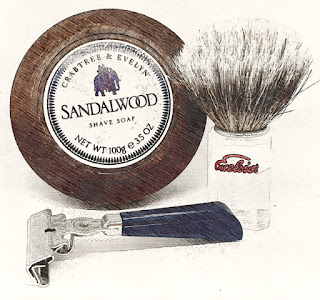

Shave of the day 29th January

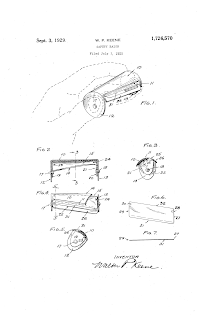

Single edge razor of of simple and economical construction

From time to time I come across patents that I’m sad didn’t make it into manufacture… and the single edge razor Mr Frank Pelosi was granted a patent for in May 1931 is one of them. It just looks, well, nice.

Mr Pelosi didn’t claim that his razor would be the best thing since sliced bread, nor that it would be a quantum leap over other razors… just that it would be, well, simpler and better. In his own words:

…an improved razor of this type which comprises a relatively few parts of simple and economical construction, which permits easy and speedy insertion or removal of a separable blade, and which may be small in size and light in weight without sacrifice of operative efficiency.

It’s was a simple twist-to-open open comb razor, which indexed the blade on a rivet mounted on the bottom plate, while the top cap was made from sheet metal and tightened by a knurled knob on the end of the handle.

…the razor comprises a handle 10 having an axial opening 11 therethrough, a guard member 12 mounted in one end of the handle, a rotatable knob or lock nut 13 at the opposite end of the handle, a lock plate 14 arranged to cooperate with the guard to hold a blade 15 therebetween, and an adjusting. stem 16 extending through the hollow handle and having one end engaging a threaded opening 17 in the nut 13 and its opposite end passing through an aperture 18 in the guard 12 and secured to the lock plate. as by a rivet or pin 19 which projects through an opening 20 in plate 14 and is headed over on the top surface of the plate. The stem and lock plate may thus be moved longitudinally of the handle by rotating the lock nut to secure the blade in working position (Fig. 3) or to separate the plate from the guard member and permit insertion or removal of the blade (Fig. 4).

Overall Mr Pelosi’s razor gives the impression of a well though out, workmanlike razor with no frills and only a little thrills. What killed it in the marked was probably the fact that it required it’s own special blades, requiring setting up manufacture of not just the razors, but also the blades.

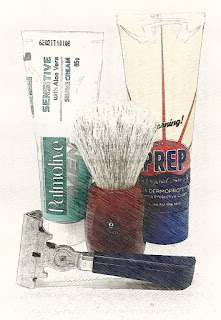

Shave of the day 27th January

Shave of the day 24th January

Safety razor with covered blade tabs

Show of hands everyone; how many of you have – at some point – given yourself a nick or cut from a exposed blade tab on a double edged blade? I suspect most of us have done it by accident at least once which is why some safety razors covers the tabs.

Back in late January 1930 – ninety years ago pretty much on the date – Albin K Peterson was granted the earliest patent I’m aware of that covers blade tabs… literally. Mr Peterson had noticed the inherent danger of the tabs, although possible not when he was shaving his beard… to quote his patent:

The Gillette type of safety razor is highly desirable because the blades can be replaced and a sharp blade always had at a small cost. In these days of scant attire for women, they often employ a safety razor for shaving unsightly hair from the arm pits. It has been found dangerous, however, to use the average safety razor, whether the Gillette or other types, because the sharp corners of the blade protrude sufficiently to cut the skin when contacting with a cupped or depressed area, such as the arm pit.

So… body-shaming the ladies in your patent filing? Classy. Anyhow – the invention don’t seem all that non-intuitive to me in hindsight, even if the patent clerk found it novel enough to grant a patent. Mr Peterson’s big idea was just a change to the shape of the top cap, made to include an overhang that covered the blade tabs. Granted; the overhangs were a bit on the large side, curved to slide smoothly in an armpit, but still just overhangs.

Interestingly enough, Mr Peterson also wanted to modify the base plate slightly to ensure a snugger fit with his improved top cap… in his own words:

The guard member consists of a curved body portion 6 to which may be secured, by shaft 2 protruding into the handle 7 and figures 6 and 7. The prongs 9 are shortened just sufficiently to fit snugly within the shields 4 thus, together with the latter, forming a complete housing for the corner of the razor blade. The prongs 8 are preferably of such a length that when the razor is assembled the tips of the prongs will be in a line forming a tangent with the outer surface of the shields 4.

It is, of course, possible to merely reduce the length of the four end prongs of the guard member of the standard Gillette type of safety razor so that it will fit into my improved blade receiving member. Thus by providing my improved blade receiving member with the standard Gillette type of safety razor, the guard member of which has, been altered as above described, the user can alternatively employ the set for shaving ‘said to be adapted to shave any part of the human body without fear of injury thereto.

Today double edged razors with covered blade tabs is fairly common, but I’ve yet to seen any with such massive overhangs as Mr Peterson suggested.

Shave of the day 22nd January

Safety razor in which it is unnecessary to separate the parts to insert the blade

Simple is often better – after all, it seems that perfection is attained not when there is nothing more to add, but when there is nothing more to remove.*

So what can be simpler than a one piece razor that you can insert and remove the blade from without opening it up? Or to go one better; such a razor, but made cheaply and easy from a single piece of sheet metal?

Walter P Keene invented just such a razor, and filed for a patent in the middle of 1925. He did this by a couple of simple metal stampings that fit one inside the other, with a helical slot for the blade. Or as the patent text describes it:

…blade is supported and held between two cylindrical surfaces with the blade edge flexed over an elongated helically cut slot…

The drawing shows how the razor should be held between thumb and fingers, allowing for good control and easy manipulation. The drawing also shows how the outer part of the shell is secured to the inner part with a pair of rivets or bolts, allowing the outer part to rotate in relation the inner part – thus opening and closing it. In the word of the patent text:

In the drawings, numeral 10 designates the outer shell or casing preferably formed of sheet metal in a punch press, consisting of an outer skin contacting surface with a helical cut tapered edge 11, the centers of the radii of this surface forming the axis of the bores formed in the side walls 12 and 13, these walls being preferably formed in planes at right angles to the axis, these walls taking the place of a handle as of the familiar hoe type of safety razor, the walls being grasped as shown by the dotted lines of a hand in Figure 1, a convenient position for use in under arm work, although an equally convenient method is to grasp the rear part of the shells as outlined by line 14:, between the thumb and fingers, either of these methods serving where the handle grasp of an operator is lost.

Supported within the outer shell is a second shell of substantially the same form, drawn of sheet metal, in which the cylindrical and approximated surface to the inner cylindrical surface of shell 10, is struck from radii of less length, so that when they are assembled, there is formed an accurate cylindrical space adapted to receive and hold the razor blade.

It’s worth noting that Mr Keene’s razor required proprietary blades – had he designed it for standard double edged blades (even if only one edge was exposed at any given time), I can actually see this razor being successful. As it is, it seems to have to sunk without a trace.

*) Antoine de Saint Exupéry, in reference to aircraft specifically but all that man do in general.