If you’re Norwegian you know what Besseggen is; a mountain ridge in Vågå kommune in Oppland county that stands between the lakes of Gjende and Bessvatnet. Often described as “sharp as a scythe”, it’s very narrow – so narow two people can’t walk side by side along the edge in places – with long and steep drops on both sides. Made famous from a passage in Henrik Ibsen’s play Peer Gynt, it’s a Norwegian national icon.

Tag Archives: Thoughts while shaving

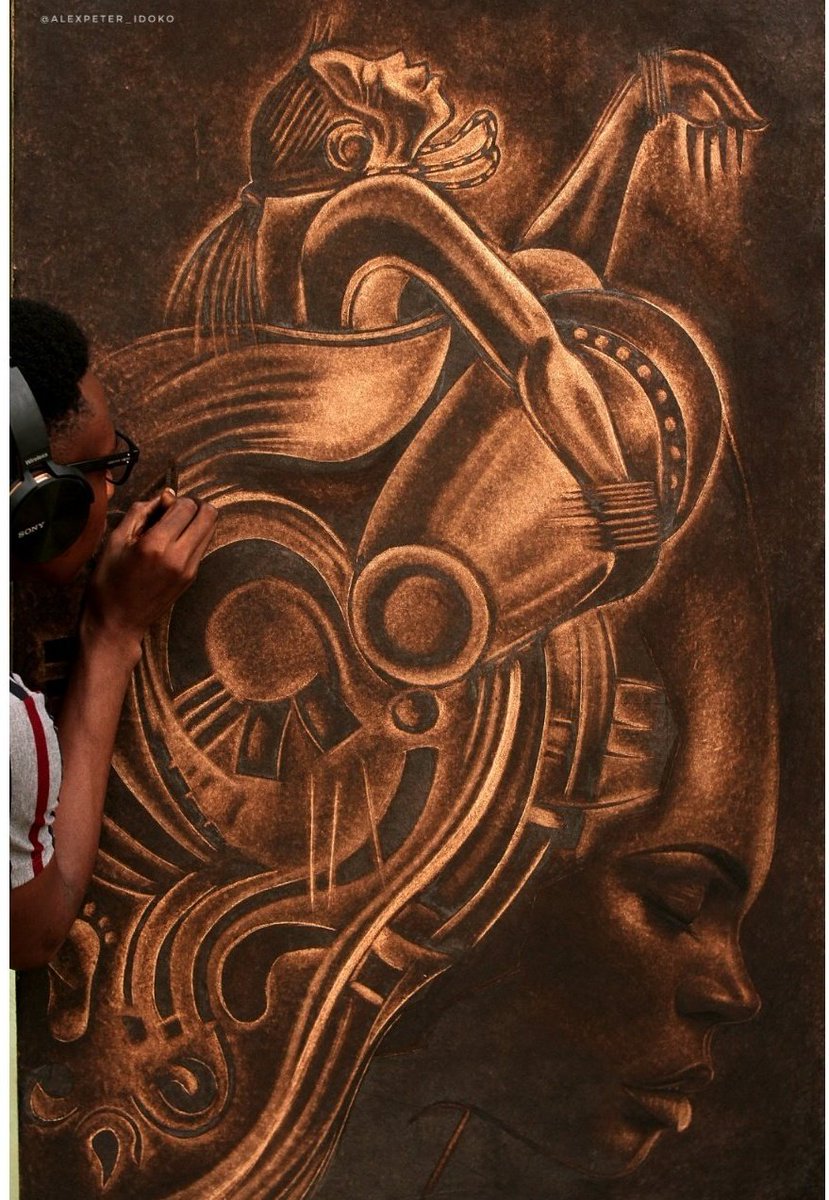

A very different use for a razor blade

Alex Peter Idoko, of Nigeria, is using razor blades for a different reason than the rest of us… making hyperrealism pyrography. And it is STUNNING! He has a tremendous knack of bringing portraits to life by using a razor blade to chip away at burnt wood.

I stumbled over him on Twitter and was blown away by his art – click the image under to make it bigger.

A couple of links for those who wants to check out more of his work:

– https://www.instagram.com/alexpeter_idoko/

– https://twitter.com/Alexpeter_idoko

Another improvement in shaving mugs

Don’t you hate it when you’re emptying your shaving mug of water and your soap falls out? Well, me neither, but just in case you do Philip Schauble and Louis Dohm, of Elizabeth, Union county, New Jersey have you covered. Or had you covered, back in 1875 when they patented an improvement in shaving mugs.

To understand why an improvement was needed, one have to recall that while a lot of us today will soak the brush, load the soap of the puck, then use a separate bowl or mug to make lather they did it differently back on the day. The soap puck was kept in the shaving mug, water was added on top, lather made on top of the puck and water then poured out… sometimes along with the soap.

Our bold inventors came up with a solution to this problem, as they stated in the very beginning of the patent letter;

Our invention consists of a shaving-cup having means for securing the soap, so that the cup may be turned upside down, for pouring out the water for cleaning it, without the loss of the soap, and without the necessity of holding it by the brush or by the hand, as is now necessary when cleaning the cup, thus saving considerable trouble and greatly facilitating the work.

In hindsight the solution Philip and Louis came up with is obvious when you read about it, but it does actually require a bit of lateral thinking. In short… who says a mug have to be smooth on the inside? What if the bottom of the mug had a screw thread mounded to the inside, like a nut that goes on the end of a bolt? And if the soap also had screw threads, like the aforementioned bolt, and could be screwed down into the mug?

As explained in the patent:

The plan which we have adopted in this case consists of screw-threads in the bottom or lower part of the cup, with corresponding threads molded in the soap, to screw it into the cup by a little forked’key or other suitable instrument…

They also outline an alternate, by having a screw that comes up through the bottom of the mug, but point out this is a much less ideal solution.

A solution they don’t touch upon in their patent might be more obvious to us today; simply have circular ridges along the inside of the mug and cast the soap in situ (i.e.:directly into the shaving mug). The downside of that solution is, off course, that soaps cannot easily be replaced.

I have no idea if this invention was ever put into production, and the patent have long since lapsed… but if any artisan or small scale manufacturer of soaps and shaving accoutrements put something like this on the market today, I would be sorely tempted. Perhaps a standard diameter and screw pitch could be agreed upon by a group of loosely organised artisans so we could choose between several of our favourite soaps… but I’m daydreaming. I guess I’ll continue to soak my brush, load from the puck and lather in a separate mug of scuttle.

A 1964 disposable plastic double edged razor

While I personally find disposable razors to be – at best – an unavoidable evil I occasionally must deal with, it can still be interesting to look at old patents for them.

Case in point; Mr Leonard W Sachs’ patent for a disposable razor with a priority date of 1964-10-26. While modern plastic disposables makes every effort to look and handle like a modern cartridge razor, his design looked very much like any other DE safety razor.

That is, off course, because it IS a fairly standard DE razor, made out of thermoplastic and heat welded together. In the words of Mr Sachs:

The head and guard members and pins are formed of an inexpensive disposable thermoplastic material deformable by the application of heat and pressure, and the pins have deformed enlarged ends to permanently secure the assembly together. A handle is secured to and projects from the guard member.

The patents states outright that the object of the invention was to make a razor cheap enough to be thrown away after one or two uses, yet good enough to provide a smooth shave. Judging by the drawings and description this was achieved. I’m not sure if Mr Sachs ever got his razor into production, but the method of construction looks remarkable similar to some of the medical prep razors you can buy all over the internet today.

Experimenting with handle shapes – part II

Two weeks ago I posted about me experimenting with handle shapes… and despite the last few weeks being busy, I’ve now used up the rest of my prepared blanks. It helps that turning a handle, sanding and finishing it with mineral oil and CA-glue only takes half an hour or so when working from a prepared blank.. and that includes time to sip coffee, thinking about the shapes, touching up the edge of my cutters and petting the friendly neighbourhood cat.

Improvement in shaving-mugs

Shaving mugs comes in all shapes and sizes, from a re-purposed plastic cup to intricate scuttles… but in this day and age you don’t often see something as complicated as the useful improvement in shaving cups that was patented by Andrew J. Fuer and Walter C. Knaus in late 1873.

It has to be remembered that this was well before hot water taps were a common fixture… I mean, as far as I know even having running water inside would be on the bleeding edge of technology, and keeping your lather warm must been a lot harder back then.

A scuttle that was simple in construction and convenient to use must have been seen as a gift from the heavens for the serious shaver, and looking through the patent shows a design that at the very least fulfils the first of those two things;

A is a cylinder made of sheet metal, and provided at its lower end with a base, B. In the lower end of the cylinder A is fitted a small lamp, C, in which may be burned kerosene, alcohol, or other burning-liquid. To the opposite sides of the lamp C are attached pins, which enter bayonet-slots in the lower end of the cylinder A, so that the lamp can be conveniently attached and detached when desired. In the lower part of the cylinder A is formed a row of holes a little below the burner of the lamp C to allow the air to pass in freely to support combustion. In the upper part of the cylinder A is formed a cup or receptacle, D, to contain water. In the side of the cylinder A, a little above the bottom of the cup D, is formed a hole leading into a small chamber, E, attached to the, side of the upper part of the cylinder A, and which should be of` sufficient size to allow the shaving-brush to be inserted. In the other side of the upper part of the cylinder A, just below the bottom of the cup D, is formed a` hole leading into the pipe F, attached to the side of the cylinder A, to serve as a chimney or line to carry off the heated air and the gaseous products of combustion, and to form a draft to promote combustion. In the upper end of the cylinder A is fitted a small cup, G, in which the soap is placed, and in which the lather is made. The cup G has a flange formed around its upper edge to rest upon the upper edge of the cylinder A, and `the said cup G should be such a depth as to extend down into the water in the cup D, so that the lather .may be kept warm.

A fairly straight forward and easy to understand description, especially for a patent. And if that was hard to follow, the drawing is also a model of clarity compared to some other patents I’ve had a look at lately.

There are a couple features of this patent that shows me that Mr Fuer and Mr Knaus at the very least had thought thigns through before applying for the patent: The bayonet-lock that makes sure the heat source stays in place, and the wide base that prevents the improved shaving mug from falling over spilling hot water and possible being a fire risk.

The only downside I see with this patent in light of when it was applied for and granted is the fact that the burner will heat up your bathroom, summer and winter – a small price to pay for hot lather.

I have no idea if this improved shaving mug ever went into production… it would be a shame if it wasn’t put on the market.

Bifurcated yoke razor

From time to time I spot an old patent where I can see what they tried to achieve, yet have to wonder about details in how they tried to achieve it.

One of those is Roger C Edson’s patent from 1968 for a razor with a pivoting head. Today a pivoting head is de rigueur when it comes to cartridge razors, but fifty years ago in the last days of the era of widespread use of DE razors it was significantly less common.

Mr Edson was obviously inspired by the double edge razor, in that his invention featured a razor head that had a cutting edge on both sides. He did however elect NOT to use DE blades, for reasons unknown. As for how he made the razor head pivot, well, lets turn to the description in the patent:

…a razor having a bifurcated yoke at one end of a handle and on which a blade carrier is pivotally mounted to rock.

Okay.. so a Y-shaped handle with the head mounted between the two arms. Of the top of my head I can think of two or three ways to mount a head that uses a DE-blade in that configuration; either using a thumbscrew underneath the head or the two arms of the handle to lock the base plate and cap securely together. Mr Edson on the other hand… well, lets read on in the patent:

The blade carrier has surfaces for replaceably mounting a pair of blades in an opposed inclined relationship with a space between adjacent cutting edges. Each of the blades then acts as a guide for the opposite blade as they are moved in opposite directions and the carrier pivots to follow the contour of the surface being shaved.

Ooookay. Two blades, not one. And it gets even stranger when you actually look at the drawings that shows the invention.

Have a closer look at figures 1, 2 and 3. Notice anything out of the ordinary? Yes, Mr Eson did opt to use machine screws and nuts to attach the blades to the razor head, would wouldn’t glide too smoothly over the skin. Yes, it does look like the blades have a certain amount of sideways play. But what I noticed first is that the cutting edges of the blades both point to the middle of the razor head!

This little detail is mentioned towards the very end of the patent, in the summary:

A safety razor comprising a handle, a blade carrier mounted to be freely rockable on the handle, means on said carrier to support and position a plurality of replaceable blades, said blade carrier constructed to mount said blades such that the shaving edges of a pair of said blades face one another and are spaced apart sufficiently for a ridge of skin to be pressed between the edges and further to mount said blades at an angle relative to each other such that when one blade is drawn flatly across the skin acting as a guard and guide for the cutting edge of the other facing blade the latter is positioned so as to produce the proper shaving angle therefor.

Needless to say I can’t find any evidence that Mr Edison’s razor was ever manufactured and sold. If nothing else the use of machine screws and nuts makes changing blades much harder than it ought to be, and that alone would be enough to doom it in the marketplace.

Weird patents: “Toilet-brush”

Sometimes a patent covers an invention which is so obviously an improvement on the state of the art that you wonder why no one have though about it before… and other times it covers an invention that history have passed by. George L Street Jr’s patent from August 1908 is one of the later.

The title of the patent is “toilet-brush”, but reading the patent makes it abundantly clear that what it means is a brushed used for a person performing one’s toilette and not for cleaning a potty. The meaning of words can drift over time…

Returning to the patent, it is claimed to be a “a certain new and useful Improvement” over previous brushes used for personal grooming, “especially applicable to shaving and tooth brushes”. As to why the brushes used for personal grooming needed to be improved, lets turn to the text of the patent:

One of the objects of the invention is to eliminate the use of a shaving cup, and cake or stick or of any detergent and holder therefor, such as is liable by repeated use to accumulate and harbor impurities and disease producing’ germs…

As to how this was to be achieved… for starters, the brushes were designed to allow easy cleaning of the base of the bristles (aka: the glue bump). This was supposedly achieved by making the brush capable of being opened up; the drawings that accompanies the text shows hinges along one side of the handle.

Freedom from the perceived bio-hazard on your shaving soap or in your shaving cup came from the ability to place soap directly inside the brush after opening it up. To quote from the patent text:

…an attenuated, pliant body of soap or detergent of proper size for a single use and which soap or detergent will lie .within or between the bristles and partake of their movement…

One version of the brush showed in the drawing includes a storage space in the handle for several of the soap wafers – useful, one would imagine, for a travel brush.

The patent also describe how the soap wafer would be made from a pliable material such as paraffined paper partially covered in soap, since soap by itself isn’t structurally sound and would disintegrate before a lather could be worked up.

With the benefit of hindsight, it’s easy to see why Mr George L Street Jr’s brush didn’t stick around… not only is the danger of germs on our soaps significantly less than the patentee seems to have believed, but a shaving brush with one or two small hinges is an invitation for a broken brush. You would also be locked in to a single source of shaving soap; however this was probably less of a worry in 1908 than most of traditional wetshavers would consider it in 2018.

No shave of the day 29th October

There is something… almost sinful about going to a professional barber for a straight razor shave. The hot towels, the massage, the pre-shave oil, the lather, the post-shave massage with a face tonic…

…and, off course, the fact that my cheeks are so smooth even the day after that I don’t have to shave on a Monday morning!

PS: Remember the unbreakable bowl from Pereira I reviewed a little while ago? It’s now available via Indiegogo, for a quite reasonable price too.

No shave, but a PSA of sorts

For various reasons – mostly to do with an idea for tomorrow – I’m not shaving today.. but I can take the time to tell you all that if you want in on the Pereira Shavery unbreakable lather bowl crowdfunder and get the bowl with 50% off shipping, you need to act soon – not only are the offer limited in number, but it only last a couple of days more.

I’m considering chipping in myself, even if I’m lucky enough to have one of these as an early sample… I wouldn’t mind a second one in a different colour, as well as more of Pereira’s soap.