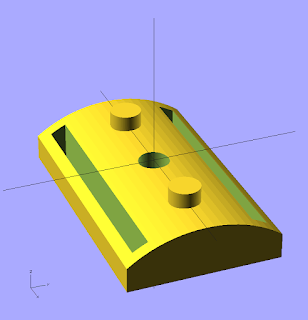

I am slowly – very slowly – getting to grips with the skill of using OpenSCAD to describe things. So far I’ve managed to come up with a ‘parametric’ file, where I can alter a variable or two to create different versions of the same object. And while the two extremes might be way too mild or way to harsh to shave with, the one in the middle might work reasonable well…

Tag Archives: Thoughts while shaving

Repacking the GoBag

A major drawback – or benefit, depending on your point of view – of my line of work is that I sometimes gets to be away from home for extended periods of time… sometimes I know in advance, sometimes I don’t.

As mentioned before I keep a GoBag ready at all times, even if the contents vary from time to time. The newest addition now is my travel sized bottle of Thayers Witch Hazel, utilizing the space freed up by switching to a smaller bottle of body wash / shampoo. There is something of a challenge to getting the most comprehensive piece of kit into the smallest possible space; akin to what the participants in the Herioc Age of Antartic Exploration had to deal with – only less glorious and less cold.

Superlather

The term “superlather” is sometimes used to refer to a combination of shave stick and cream. I discovered it more or less by accident a couple of months back, and have slowly been experimenting with it.

While I’m not done yet, the preliminary findings are fairly clear: using both shave stick and cream gives you a lather that is dense, rich and above all thirsty – plenty of water is needed to make it work.

Playing with plans for 3D printed razors

Pay It Forward

Wetshaving in the internet-age isn’t just about getting a damn fine shave while (potentially) spending significantly less money that you would if you went for canned goo and cartridges.

It is also about – at least for some of us – social interaction with others with whom we share a hobby. Being active on an online forum means you get to share hints, tips and sometimes more… many wetshavers are happy to Pay It Forward, which can both serve to give other shavers a chance to try something new as well as culling the horde some of us accumulate.

To mark my 1000th post over at The Shave Nook – a very friendly and open minded shaving forum – I decided to pay forward a tub of Mama Bear’s Brazilian Coffee that I’ve barely touched. With luck the guy who got it will enjoy it – and in time pay the favour forward.

Soaps, croaps and creams

It is amazing really – no matter how often you shave, the sheer amount of soaps and creams don’t seem to be reduced.

Clearly the reason for this apparent miracle is that we’re living in the future now, and soaps, croaps and creams have become self-replicating… it’s the only logical solution. The other hypothesis – that they breed – is just too… off-putting.

3D printed razor

The idea of using a 3D printer to make shave gear have taken firmly root in my head, to the point where I find myself messing around with free 3D-CAD software just to try to visualize how razors and brushes could be created… someone beat me to it though:

More on angles

Angle of Attack

If you’ll excuse the aeronautical term, the angle of the blade have been somewhat on my mind lately – not the angle it has in regards to the razor (which differs between various razors), but the angle it has in regards to the skin when it cuts.

It is – like many other things – the fault of the cartridge shaving systems… the so called modern razor tends to have a flexible head, which is supposed to make shaving easier. A cartridge razor teaches us a lot of bad habits – use of excessive pressure is the one mentioned most often, but just as bad is the lack of proper angle… and when shaving DE (or SE) the angle of attack is alpha and omega in my opinion for getting that great shave.

The head of a traditional safety razor does NOT pivot. Therefore the pivoting action have to come from the wrist – making shaving a little more labour intensive, but more importantly giving the shaver near perfect control… unlike a wibbly-wobbly plastic hinge.

Maintain proper AoA at all times – and check your six for bogeys.

/ for a more complete discussion on the how and why of the shaving angle, please see this article over at the Badger & Blade wiki

Make your own shave gear

The post the other day where I showed an old time razor made from a bent metal plate made me think of 3D printed razors. I figured that if I could come up with that idea, so could other clever people, so I headed over to Thingiverse – one of the better known places online to share all things 3D printed.

No razors – at least that I could find – but plenty of shaving gear. A few I liked:

– A fancy razor stand

– A less fancy razor stand

– A combined razor and brush stand

– A combined razor and brush ‘hang’

– A shave brush handle

– A blade disposal box

Now, if I could only justify spending a huge wad of cash to buy a 3D printer I would have all the razor stands I would ever need… but no printed razor.