King of them all! …well, possible ahead of the pack early last century at least.

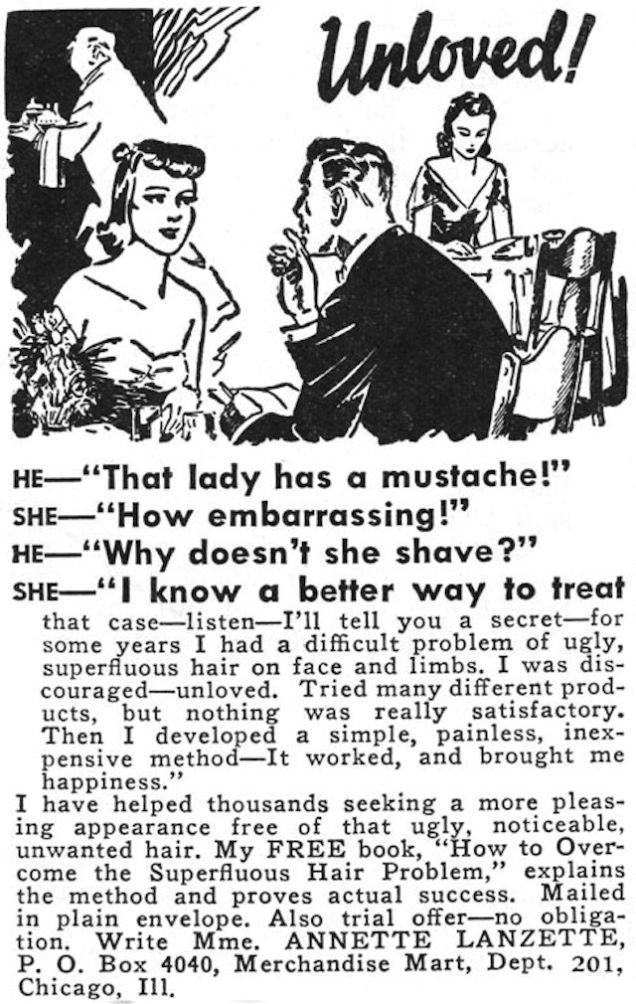

An advertisement from 2 September 1905 that I stumbled over at Wikimedia that peeked my interest.

While I do doubt the claim of 20-40 shaves per blade, it could be that the thicker carbon-steel blades kept their edges longer than the thinner stainless steel blades we use in this day and age. Or might people have coaxed that many shaves out of them due to the cost of replacement, much like many people today pushes as many shaves as they can out of cartridges before shelling out for new ones?

Taking inflation into account, the set of a razor with a dozen blades would set you back 146$ today – a not insignificant investment. A replacement pack of twelve blades would cost just shy of 30$… which is definitely in the same league as replacement cartridges today. If I paid 2.50$ per blade, I would try to coax a month of shaves out of it too.

In a way it makes sense that Gillette would charge as much for blades back then as they do for carts today. The safety razor wasn’t about liberating men from the tyranny of the barbershop, or helping the working stiff save money… it was about creating a market with vendor lock in and a steady revenue stream. People invest in a razor, and will return year after year to buy blades… and as long as you control the patents, you have in effect a walled garden. Other manufacturers can’t step in to offer compatible blades cheaper without infringing on your patent, and the users can’t get out without giving up on the money they have invested so far (the sunk cost fallacy).

Shaving with an old fashioned safety razor might save you money compared to the alternatives today, but when the old fashioned was the cutting edge, you paid to be part of the first adopters.